Sectional Hard Floor Assembly

Please download the Aluminum Floor Assembly Manual for more details.

- Installing the hard floor for the first time may seem a bit difficult, but it will get easier and faster with each assembly and disassembly.

- It’s best to have at least two people help, especially for the first few times.

- The keel is usually folded sideways during packing. For the first installation, inflate the keel and position it so the air valve is on top and centered. Then deflate the keel while keeping the valve on top. This helps position the keel valve correctly against the front floor piece opening.

- Aluminum side stringers are designed to cover the joints between floor blocks—they don’t run the entire length of the floor.

- Keep sharp edges of the aluminum floor away from the tubes, or cover them with duct tape or painter’s tape during installation.

- Place the floorboards inside the boat hull so there are equal spaces between the edges of the boards and the boat bottom. These spaces are needed to install the stringers.

- Start installing from the front board (#1) and work toward the middle of the boat. Then install the rear boards and work toward the already installed boards.

- The two floorboards in the middle will slightly overlap. Lift them and position them like a roof shape. Then step on them carefully; this will flatten the boards inside the boat.

- Place one assembled rowing oar on the ground along the boat bottom. Lift the boat side and push the oar slightly under the boat to lift the floorboard edges. This makes it easier to slide the stringers over the edges. Repeat on the other side.

- After installing the floor, fully inflate the tubes to press the stringers into the floor channels. The boat tubes should have no wrinkles and feel firm to the touch.

|

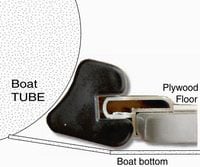

Hard floor assembly details (Plywood or Aluminum) |

||

|

|

|

| Insert stringers into side edges of floorboards. Side edges of floorboard should easily fit into C-channel of stringer. | ||

|

|

|

| Top View | Bottom View | Correct stringer position |

|

Step-by-step instruction on assembly of plywood or aluminum floors. |

|

| Inflate boat about 20% and insert front bow section of the floor. |

|

| Insert second and last sections of the floor. |

|

| Two middle sections will create roof-like structure. |

|

| Step on raised part of two connected floor sections. |

|

| Make sure that floor will flatten by spreading inside the boat. |

|

| Insert aluminum stringers between boat tubes and floor sections. It would be easier to do if oar or paddle will be placed between ground and boat bottom, such way that to lift edge of board off the ground. |

|

| Aluminum stringers should connect at least two or more floor sections. Ensure that all floorboard joints are covered by stringers. Do not push the stringers all the way toward the transom. It is acceptable to have spaces between adjacent stringers. |

|

| Inflate left and right tube of the boat. Use hand pump to finish. |

|

| Inflate bow section of the boat. Use hand pump to finish. |

|

|

|

Last step is to inflate keel of the boat with a hand or electric pump. |